Heerema Engineering Solutions

XL Monopile Structural Integrity for Transport & Installation

Heerema Engineering Solutions was selected by Vattenfall to perform a monopile structural integrity study.

XL Monopile Structural Integrity for Transport & Installation

Wind turbine generators are growing in size and capacity while being installed in deeper waters, resulting in a requirement for larger monopile foundations. The offshore installation of these XL monopile foundations results in new challenges. One of these challenges is to ensure the monopile structural integrity throughout the complete transportation and installation process.

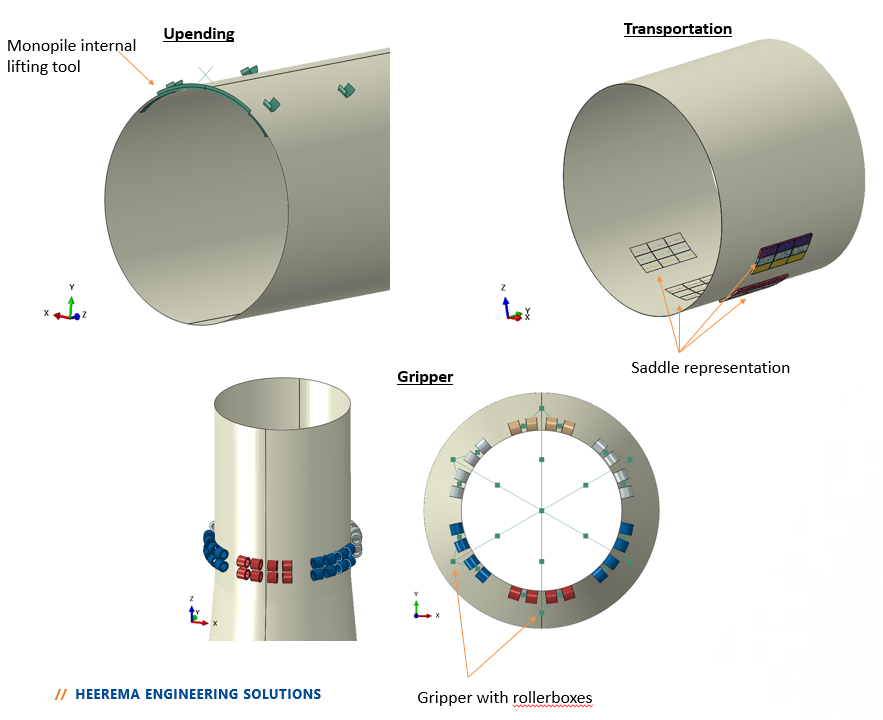

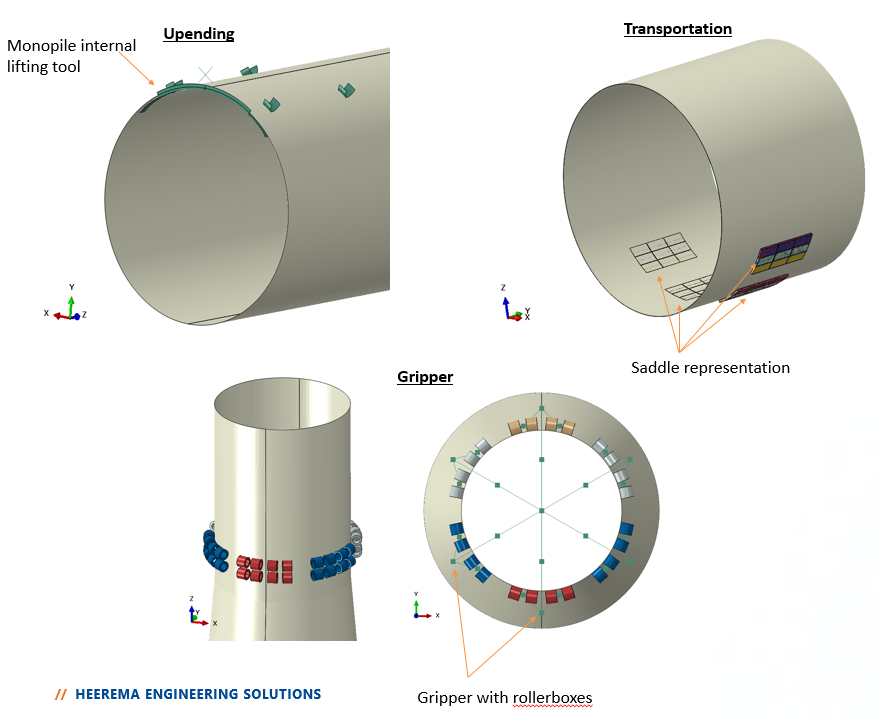

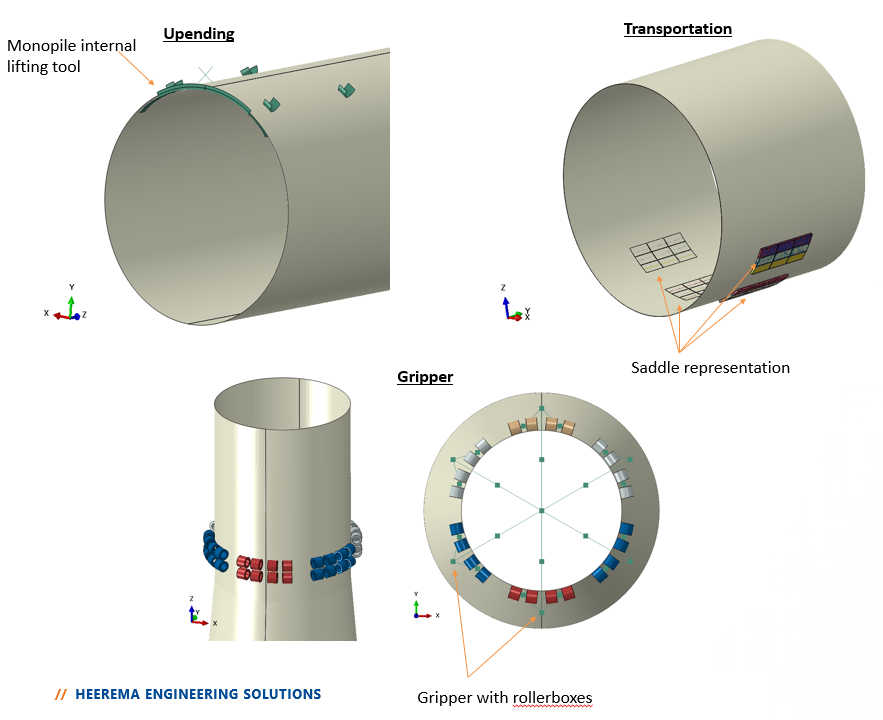

Heerema Engineering Solutions has an extensive track record in engineering related to the offshore installation of large structures and ensuring the integrity of those structures during transport and installation. For this reason, Heerema Engineering Solutions was selected by Vattenfall to perform a monopile structural integrity study. The aim of this study is to confirm that the following transport and installation steps can be executed without jeopardizing the monopile structural integrity.

- Offshore transportation

- Upending of the monopile

- Motion-compensated monopile gripper frame operations

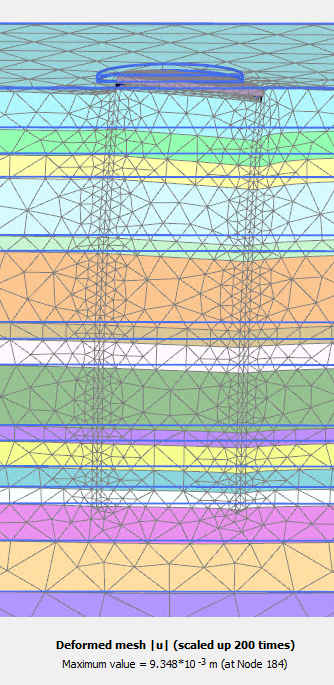

For this study the finite element analysis software Abaqus is used to calculate the stresses occurring in the monopile due to self-weight, operational loads, and environmental loads. The load introduction from the installation & transportation aids into the monopile is analyzed to understand the stresses occurring in the monopile. This study shows that the load introduction interface has to be designed with great care because the monopile integrity highly depends on the design of the installation and transportation aids.

The result of this study shows that when the interface between the monopile and the installation or transportation aid is properly designed the stress distribution is acceptable. Hence no specific requirements with regards to the above installation steps have to be added to the monopile design.

XL Monopiles - Wave Slamming During Transport

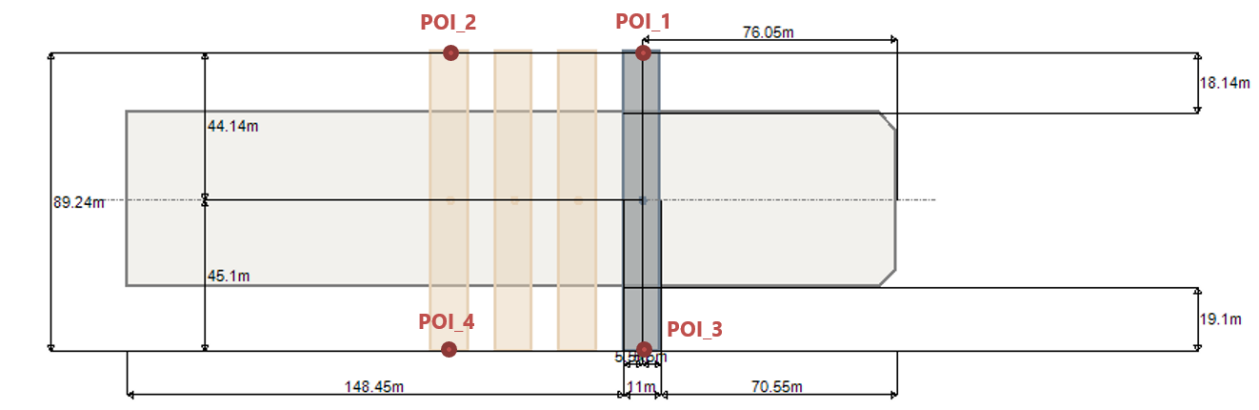

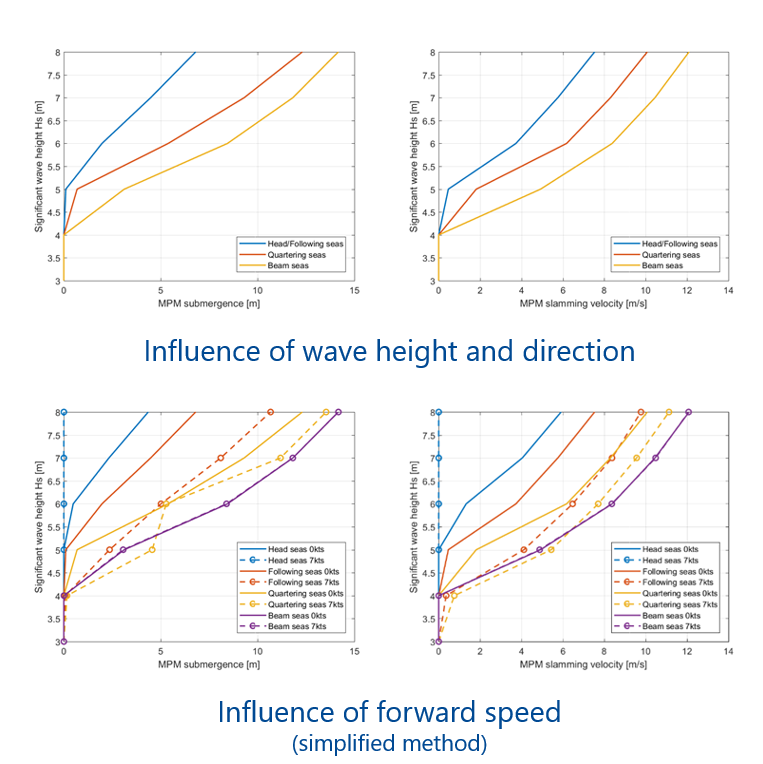

XL Monopiles (MP) are transported offshore on cargo vessels. In several configurations, the monopiles are positioned transversally on the vessel deck. Resulting in a significant MP overhang on either side of the vessel. Depending on the environmental conditions and the hydrodynamic behavior of the vessel the MP sections that extend beyond the vessel side shell might become subject to wave slamming. This study is executed to understand the occurrence of slamming and the resulting impact loads.

For this study, a time-domain analysis was performed with in-house developed software. Occurrences of slamming events, submergence, and slamming velocity at points of interest (monopiles overhanging ends) were computed. The results can be used to derive slamming forces acting on the monopiles.

Example deck lay-out and calculated results are presented in the below figures.

XL Monopile Stability during installation with a Dynamic Positioning (DP) gripper frame

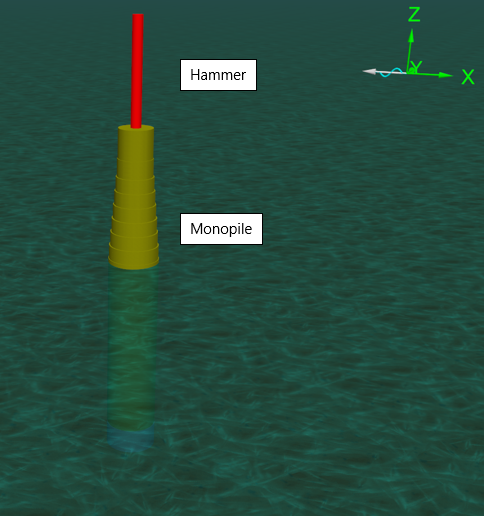

XL Monopiles could be installed by using a DP gripper frame. Depending on the vessel considered, the center of the gripper frame installing the MP is located at a certain level above the waterline. A stability assessment of the XL monopile for the moment when the gripper is retracted is required to determine the feasibility of the XL monopile installation with a specific vessel in combination with the DP gripper frame system.

A time-domain Orcaflex analysis considering certain environmental conditions is executed to determine the loads on the monopile just above the seafloor. This analysis is used to determine the shear load and bending moment in the monopile just above the seabed. The shear load and bending moment are then combined with site-specific soil data in a PLAXIS analysis. This analysis is used to calculate the rotation and deflection of the monopile just above the seabed. These parameters provide insight into the stability of the monopile during the above-defined installation step in certain environmental conditions.

In the below figures the Orcaflex model and the Plaxis model are shown.

|

|

/People%20for%20job.jpg?width=600&name=People%20for%20job.jpg)

Are you ready to make waves?

Join the Heerema team!